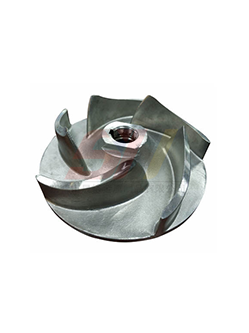

High Precision Casting stainless steel pump impeller Parts

| The following data are for reference only, subject to the material object | |

| Product name | Stainless steel impeller for Investment casting |

| Brand | SHENGYU |

| Material | Stainless Steel ,Alloy steel,carbon steel,heat-resistant steel,Brass,Aluminum etc. |

| Surface Finishing | Shot blasting, pickling, sand blasting, etc. |

| Tech | Investment casting+CNC |

| Sample Delivery time | By air express 30-35days arrived after ordered |

| Batch Delivery Time | 35-40 days |

| Payment | Credit card , Master card , Paypal , T/T |

| Certificates | TUV, ISO9001,ISO14001 |

| Size | Customized |

| Process | Investment casting+CNC |

| Tolerance | +/-0.01 -+/-0.05mm,can also be customized.? |

| Standard | AISI,ATSM,UNI,BS,DIN,JIS,GB etc. |

| Design | Various type of 2D or 3D drawings are acceptable,such as JPG,PDF,DWG,DXF,IGS,STP,X_T,SLDPRT etc. |

| Inspection | Dimension inspection; Chemical composition analysis (Spectrum analysis); |

| OEM&ODM | OEM&ODM are accepted. |

| Quality System | 100% Inspection before shipment |

Application industry

Our products mainly involve following areas ,fluid equipment parts,Pumps & Valves,Impeller Parts,,Building Hardware, Marine Hardware, Automobile and Fabrication customized parts.

Tags products

Shengyu

Shengyu

Leave a Message